Hi guys.

This is an Aria baritone classical guitar. It has a loose jack and it sticks out badly. The trouble is that I cannot reach the darn thing, even my best half cannot reach it. Anyway since I don't know what the production method was, I was wondering if anyone has an idea to share.

I don't know what size the nut is, but I assume it's metric since it's made in Spain and the barrel is a little over 10mm, so this narrows it down a bit. What would you guys do? I don't have skinny hands and forearms, but I never had problems reaching the endblock not even on a 3/4 classicals. This one really takes the cake, I can only reach the very end of the jack, just barely touching it with my middle finger.

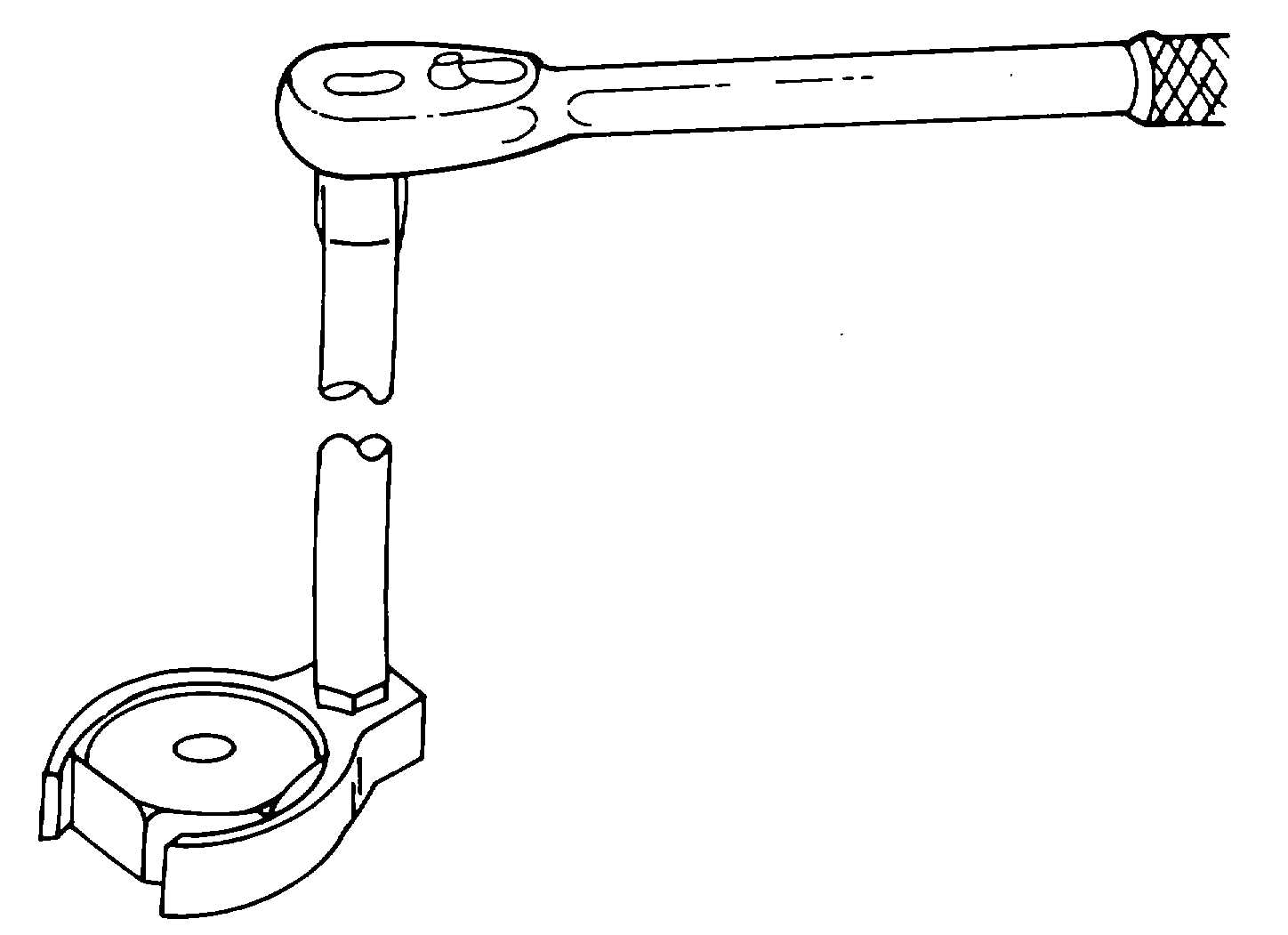

The best thing I can come up with is to bend an appropriate wrench to an L-shape. Or just cut a trapezoid notch in a thick strip of aluminium 12-15 mm, and bend it too. I think I'll take some time on this one, because the nut is probably on it's last few turns.

Any ideas?

Thanks!

Views: 467

Replies to This Discussion

-

Years ago I bent a 90 degree "L" in a wrench for tightening those loose inside nuts. Now there are endpon jacks that tighten from the outside, much better. I also add a large lock washer from the hardware store to help keep the jack tight. There were several times the loose jack had to be cut off from the outside as the inside nut had been crossthreaded and would not come off.

-

Hi Tad,

There is a specialist slotted nut driver thingy that I've seen, but I don't have one and can't say whether that's the way.

I see Frank has come to the party with the sweet engineering solution, but if that's not doable in your neck of the woods I subserviently offer the following way to REMOVE the jack so you replace it with a modern jack that tightens from the outside (Switchcraft/Fishman style). Spend half a day tightening this sucker and the time wasted is more than the cost of remove and replace.

There are "bent tip" long nosed pliers (8 to 12" long) that will help you get a grip, so as to speak: hardware stores maybe - automotive tools store certainly and they aren't so expensive (Ebay).

You will need to be able to see inside the box so a light and mirror is good - or a mobile phone/digital camera shot will help determine what you are up against. A bore-o-scope or gooseneck inspection camera is the best and can give you real time imagery while you are manouevering in the confined spaces but you need a few of these types of jobs to make them pay (a lot of folk here use them for brace, bridgeplate and crack work inside the box as well)

Push the jack back into the box as far as it will go and tape (or get your mate to hold) the endpin to prevent rotation while you are initially getting the pliers to grip the nut, then the jack by turning the outside of the box part of the jack rather than trying to turn the inside bit (cut the lead before you do this).

You can feel where the nut is with the tips of the pliers even if you can't see it.

Second one, and I've done this - if you can see the nut or threaded cylindrical sleeve with a mirror etc and it is free turning - put a small square of double sided tape on the end of screwdriver and hold it against the edge of the nut while you turn the barrel from the outside - you need some feel here and don't get the tape on the barrel section otherwize it will lock everything up.

Good luck with this one - otherwize get a supermodel girlfriend with arms like a spider and ask her for a favor.

Rusty.

-

You can also buy a wrench that a plumber would use to install or remove the fossets on a kichen sink it has a long handel and is open on the end just like Franks wrench has.Bill.............

-

Nope, not trading my girl for anyone else ;)

Thank you for your input guys. I got the nut snug now after Rusty's and John's suggestion. I took a chinese chopstick and stuck some double-sided tape to the rectangular side.

I took a look down the socket, and it looks like deep down there's a "Y" shaped indentation. I'll go and unhook the battery to keep it from shorting and try to turn it. Luckily enough I can see the serrated washer behind the nut.

-

Problem solved. Silly I came up with the best idea while I was topping up my windshield cleaner, I checked the ignition cables and then it struck me. I took my small engine spark plug wrenches, even the cable went through smoothly, it's tight as it'll ever be now. The nut is a 14mm :) It's a Shadow 861 preamp.

- Attachments:

-

For the Switchcraft 152b I used the eraser end of a pencil to get the nut close to tight and then a wrench like Franks. (we should get t-shirts made with WWFD on them)

I believe these guitars were introduced around the time the EMG under saddle pickup system came out. If it's one of those, you have to stick an allen key down the middle of the jack from the outside and tighten it, there are 3 or 4 bearings that push out and grip to the sides of the hole.

-

Medical hemostats? I've got some custom bent ones to grab pots inside of 335 style hollow bodies.

© 2026 Created by Frank Ford.

Powered by

![]()