Hairline cracks glued with hot hide glue are stable and new cracks will probably come next to the glued crack. But HHG don't fill out voids and larger cracks will not be as strong, hence the cleats. Working through the soundhole, the standard pyramid shaped cleat in spruce or some other wood is the way to do it. I have the luxury to have the bottom off almost all the time and I use cleat strips to cover the whole crack, at least on the bottom cracks. On the top I use a row of smaller cleats to cover the crack.

I had a hard time making these cleat strips, tried many ways to do them by hand without great results and always with sore fingertips! Instead I made a jig.

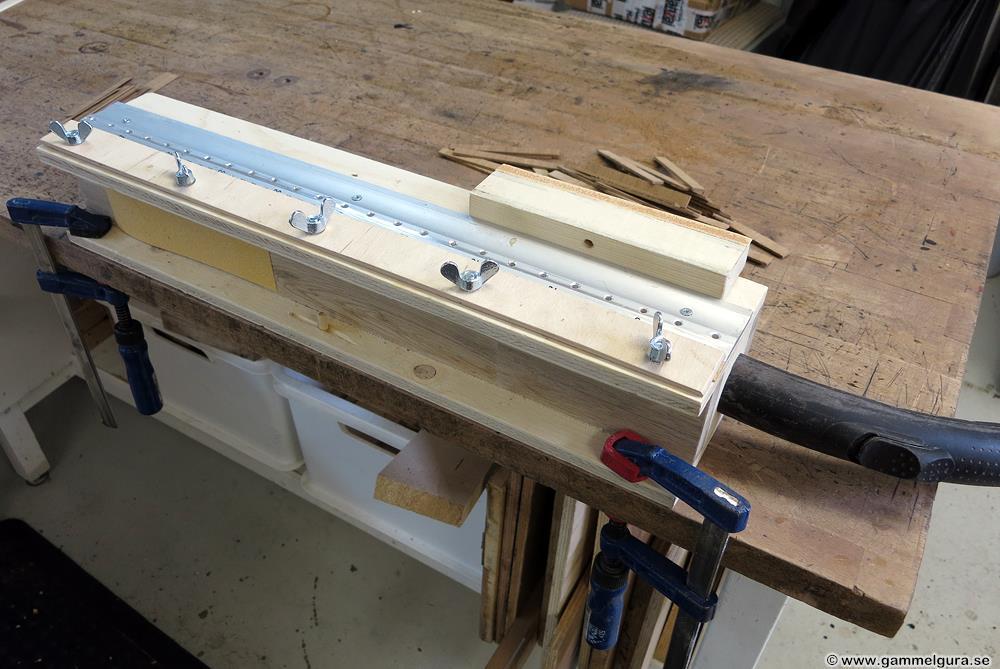

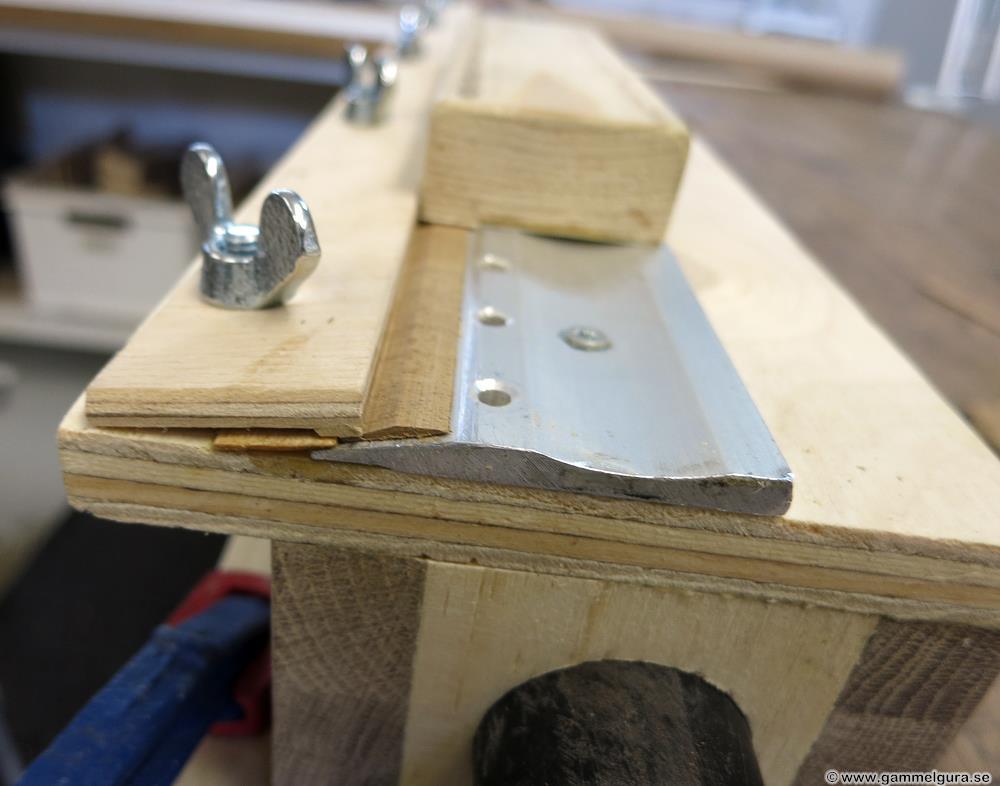

This Macgyver jig is made around a cut down steel ruler, the slant on the measuring edge was just right. I use coarse sandpaper to shape the strip and that makes a lot of dust, so I made a vacuum chamber for my shop vacuum cleaner.

The sanding block and some extra sanding paper is attached to the jig for safe keeping. The sandpaper strip on the block is level with the rest of the surface of the sanding block.

I needed some cleat strips in a dark color, so I made blanks cutting up a 2 mm thick mahogany side to 1 cm wide strips. The cleat strip should have the grain across the crack.

The blanks are fixed under the plywood list with wingnuts. There are thin strips of wood under the plywood list to make the blank stand out 5 mm and clamp it.

The blanks are fixed under the plywood list with wingnuts. There are thin strips of wood under the plywood list to make the blank stand out 5 mm and clamp it.

Five blanks could be clamped in at the time in the jig and sanded down on one side to a nice slope.

Five blanks could be clamped in at the time in the jig and sanded down on one side to a nice slope.

... and then on the other side.

... and then on the other side.

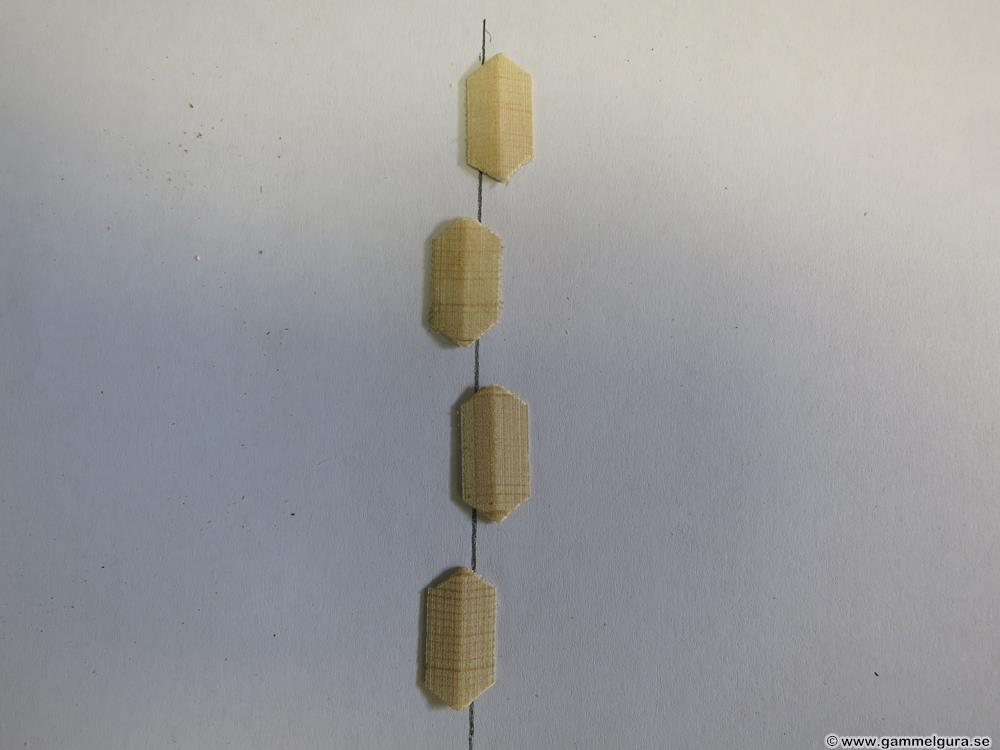

The end result is nice! Perfectly triangular, light and shaped cleat strips.

The end result is nice! Perfectly triangular, light and shaped cleat strips.

A couple of slide to explain how I glue the cleats on the top. I don't want to stiffen the top too much with a solid cleat strip. I don't want the side of the strip act as a point for the next crack. I cut the strip, make the ends pointy and glue them in a zig-zag pattern over the crack. Easy to follow bent cracks too.

A couple of slide to explain how I glue the cleats on the top. I don't want to stiffen the top too much with a solid cleat strip. I don't want the side of the strip act as a point for the next crack. I cut the strip, make the ends pointy and glue them in a zig-zag pattern over the crack. Easy to follow bent cracks too.

I make batches of these and keep them in a paper tube. Easy to use when needed :-)

I make batches of these and keep them in a paper tube. Easy to use when needed :-)

Views: 664

© 2026 Created by Frank Ford.

Powered by

![]()