Does anyone know if the StewMac Precision Router Base will work with the Proxxon IB/E?

Also, is the StewMac the only and best option? I guess I'm wondering about the durability of an acrylic jig.

Views: 6228

Replies to This Discussion

-

Sorry...is the StewMac Bridge Routing Jig the only and best option? I was impressed with Frank Ford's Bridge Mill (http://www.frets.com/FretsPages/Luthier/Technique/ToolMaking/Bridge...) and in comparison the acrylic jig looks puny.

BTW, StewMac says the Precision Router Base fits anything with a 3/4"-12tpi nose.

-

Hi Robbie... I've had pretty good luck with the SM jig, but there was a learning curve. I've found you can't have too many clamps holding it in place... it tends to scoot-around otherwise. The fact that's it's acrylic is a plus in my book because of the visibility factor. I use a Foredom 3/4-12tpi handpiece, which is skinny and also helps the vision issue.

Can't speak to the longterm durability as I've only used it maybe 15-20 times but, so far... so good. It pays to tighten all the stops down hard and recheck them a few times before cutting commences. And again... clamp that puppy down solid.

Frank's jig looks absolutely killer! I wish someone would produce one commercially, but the cost might be a show-stopper in the long run.

-

Is there anything that be put on the bottom of the plexi to help it remain in place? I'd hate to have the jig slip as I'm doing a customer's bridge.

Another issue for me is the rotary tool/laminate router issue. I can't see buying both the jig and a Colt right now. I'd like to use my Proxxon for the time being. I have a Dremel but the Proxxon is smoother and has more torque.

Unfortunately the Proxxon doesn't have a threaded nose. A guy on the Lumberjocks forum says he was able to adapt the Proxxon hand piece to fit the Precision Router Base.

-

I have the Stew-Mac bridge slotting jig and don't use it anymore...

The reason(s) are:

1) Dremel based (in my case) and Dremels basically suck in terms of available power and too much runout. The runout issue can be at least partially addressed by shimming the bearings in creative ways. But even the brand new Dremels that I have checked still have an unacceptable level of runout right out of the box.

2) The Stew-Mac bridge slotting jig works but the precision is not there in my view. Too much slop and the guide that fits in the space for the guide in order to move it has to be free to move and this is where some of the slop enters the equation as well.

3) As Mike said you have to secure the heck out of it too or it will move around - not good.

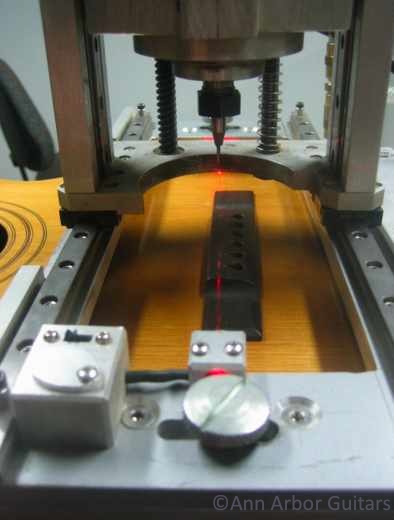

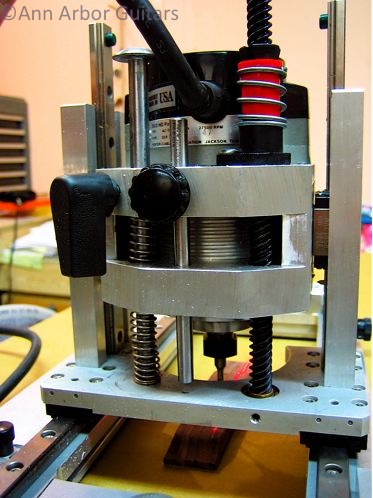

I stopped using my Stew-Mac jig for these reasons and the fact that David Collins, my business partner designed and built a killer bridge slotting jig that addresses all of the issues above and more. It's laser guided.... (don't tell the NSA...;)), milled aluminum, vacuum secured to the guitar, can do the most micro of micro adjustments, and best of all employes the excellent PC-310 trimmer for it's power and lack of runout. They don't make the 310 anymore but these things last for decades and can be serviced when and if they need new bearings.

The down side is that one needs a vacuum pump and connections but beyond that the jig and PC-310 produce super accurate and true saddle slots.

-

I have the Stewmac jig, and as has already been said, it works well if you clamp it properly. But a dremel is useless for use with it. The Stewmac jig comes with an extra base for the Bosch colt, and that's what I use, as I use the Bosch in other jigs too. I just change the base if nessasary, just 4 machine screws, doesn't take long.

In comparison to the dremel, the Bosch has proper bearings, a 600W motor, and a really solid collet. For this kind of work, the dremel is an imprecise toy. When mine goes bust (which is unlikely as I hardly use it, due to lack of power and iffy bearings), I certainly wouldn't buy another

The Proxxons I have seen don't impress me: Like a dremel painted green, but with the same disadvantages for this kind of work

-

I have to disagree about the Dremels. They may not be the tool of choice for bridge slots, but compared to Dremels they are in a different league. I have burnt out 2 Dremels. I have a replacement they sent but I use the Proxxon. It's smooth, vibration free, and has more torque. It doesn't bog down and seems to maintain RPMs under load. It's made in Germany which says a lot.

-

Very nice! The laser puts a line on the bridge for jig orienting and the vacuum holds it against the guitar? Are there stops for doing blind slots?

That's a massive router.

-

You've got it Robbie and I'll post some more pics so you can see how it works.

It works great in all respects and works so very well in fact that it can change how one works. More specifically we never shy away from cleaning up nasty saddle slots because this jigs gives us the confidence to know in advance that we can do what we wish time and time again. When we make bridges they are now slotted on the guitar and not as part of the bridge making. This also takes some of the stress out of bridge placement because we also know that we can mill the slot exactly where it needs to be for the specific instrument.

There is zero slop in this thing and the term "like it's on rails" wholeheartedly applies to this jig.

-

Beautiful. Nothing like a well designed and executed tool. You guys should be proud of that one.

-

Thanks Robbie! David Collins designed and built this saddle mill so he gets all the credit and I get all the blame.... ;)

-

Hesh...what brand bits do you use? I just tried ordering the StewMac ones but the 5-piece set is 2-3 weeks back-ordered. I only wanted the 3/32 but it's BO too.

© 2025 Created by Frank Ford.

Powered by

![]()