This is the last installment of my trilogy containing the "composite saddle bone", the "spruce bridge plate" and now the "nut compensation". These three things works in harmony on my restored old guitars and to my ears gives them a way better sound than expected :-)

Intonation is a field with many theories and opinions. Here I describe a practical way to use the nut and not just the saddle to improve intonation on any fretted instrument. The information found in the site setitupbetter.com is the base for the method.

To use the nut for intonation purposes gives the possibility to have almost "perfect" intonation on two different spots on the fretboard. With standard intonation the intonation will be great at the 12'th fret only. The intonation in the upper fret area of the fretboard are really bad indeed. Incidentally, that's where the majority of all guitar players play their chords ;-)

The main problem is that all fretted notes have a higher pitch than the open strings due to the stretching of the fretted strings. Another major problem is the need to have the nut a bit higher to avoid fret buzz from open strings (they are longer, vibrates more and are often played harder than fretted notes, back buzz behind a capo is another problem). Chords with a blend of fretted notes and open strings will sound out of tune with the standard intonation, especially the chords taken near the nut.

After reading the info on the site mentioned above, I came up with a way to measure the intonation points in the nut and the saddle. Using the measures I then cut the fingerboard shorter (around 1 mm shorter) at the nut and use a dremel and files to shape the nut and saddle so the string leaves the nut/saddle at the measured intonation points.

I use a stroboscope tuner and use it to make sure that the open string, the fretted third and 12'th notes on each string is in tune. I do this by moving the intonation points at the nut and saddle to a forth (retuning after every movement) until the equation is solved and all the three notes on the string is in tune. The positions are measured and written down.

While measuring, the "nut" consists of small bits of tangless frets acting as an adjustable "zero fret" and the "saddle" is the back ends of drills rolling on top of the bridge. A temporary tailpiece is used to fasten the strings. A small piece of spruce is used to make the fretboard a bit longer at the nut to make room for the movable frets, a 0.15 mm feeler gauge gives the "nut" a bit more height to emulate the optimal string height at the 1'th fret. Another piece of spruce is needed to fill out the saddle slot if there is one.

It's easier on an electric guitar, no need for a tailpiece and drills.

It's easier on an electric guitar, no need for a tailpiece and drills.

The final intonation points on the electric guitar above. Small compensations on the nut was needed on this one, but I had to extend the width of the nut about 1 mm closer to the 1'th fret.

I measure the distance from the back side of the 1'th fret to the middle of the "zero" fret for each string with a digital caliper and the distance from the same backside of the 1'th fret to the intonations point at the saddle with a ruler. I put the measurements in a table (mm and cm).

It's important to check the string height at the 12'th fret, it shall be the one used when playing. For the electric guitar I use a standard 2,5/1,5 mm between the top of the fret to the underside of the string. Having the stringset that the player likes and will use is another good thing to make the intonation as good as possible. The tuning shall be the one most used when playing. The fretboard should have the right relief too. In a nutshell, all the setups and choices should be done before the measuring for intonation.

By cutting the fretboard shorter at the position for the intonation point closest to the 1'th fret, the nut can be rectangular and all the other intonation points can be reached with a dremel. The nut looked like this when cut. Only with a close inspection of the nut you will notice the jagged cuts.

Not a great example, the G and D came close and I decided to leave both of them uncut when measuring the nut blank on the guitar... I should have cut in 0.16 mm on the G string...

Every guitar have small variations of the intonation points. There is no "one size fits all".

On acoustic guitars I have noticed though that it's the A or b strings that usually comes closest to the 1'th fret. At the saddle the strings G-e is often a straight line and the E-D strings can vary a lot. The electric guitar example above is not typical, the variations at the nut is usually bigger.

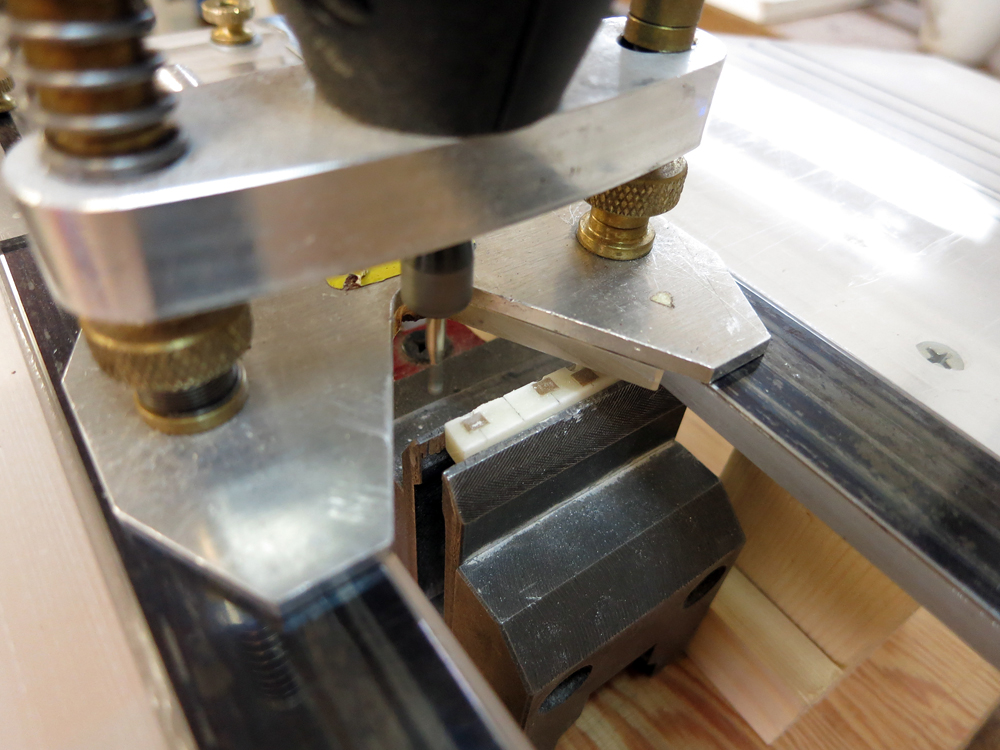

I made a special tool to shuffle the fret bits at the nut like this.

I found a drill bit set with drills in steps of 0.1 mm between 6 mm to 0.1 mm. Very handy to adjust the string height at the 12'th fret with a radiused fretboard. I mark the position of the intonation point on the nut blank with small bits of tape to make it easier to cut in to the right spot.

I found a drill bit set with drills in steps of 0.1 mm between 6 mm to 0.1 mm. Very handy to adjust the string height at the 12'th fret with a radiused fretboard. I mark the position of the intonation point on the nut blank with small bits of tape to make it easier to cut in to the right spot.

I made a jig for the Dremel using my modified version of the Stewmac saddle slot jig.

I made a jig for the Dremel using my modified version of the Stewmac saddle slot jig.

Here is the finished nut, a rather typical one for an acoustic guitar.

Here is the finished nut, a rather typical one for an acoustic guitar.

Doing a nut compensation like this makes the guitar chords near the nut play beautifully in tune. I believe that even a capo will play better since the saddle is only intonated for fretted notes (as the capo is) instead of a blend of fretted notes and the problems at the nut!

Doing a nut compensation like this makes the guitar chords near the nut play beautifully in tune. I believe that even a capo will play better since the saddle is only intonated for fretted notes (as the capo is) instead of a blend of fretted notes and the problems at the nut!

Without a nut compensation, every fretted instrument WILL be out of tune when playing chords near the nut. The difference is is a major one.

The nut intonations is quite stable. The intonation is very good even when a different set of string gauges or alternative tunings are used. I for one is not as sensitive to pitch as the stroboscope tuner is! On an electric guitar it's always a good thing to intonate the "good old way" for the new set of strings, that will make the guitar play cleaner in the lower part of the fretboard. There are always variations between different sets of the same string brand, but most of the time the difference is small.

The measuring process usually take me one hour. Making the compensated nut and composite saddle another couple of hours. All in all, it's about a half a days work if nothing goes wrong. The upside is the result obviously, but the measurements also makes it impossible to cut the saddle slot in the wrong position :-)

Views: 12384

Replies to This Discussion

-

It's 0.4 mm between the fret top and the underside of the strings. Looking at Stewmac's recommendations they say 0.61 mm. Way too high in my opinion. I think the picture is deceiving, the 7.25 radius does that.

I check the setup closely, both on the 1'th fret and the 12'th fret for each string when I do the intonation measures. The variation is there, no one guitar is exactly the same as the other. Sometimes I think it's way off and change the string. A couple of time the string was indeed faulty, but most of the time I get about the same result.

Before I do the intonation I work with the fretboard and the frets. I have a carbon rod in the neck, no trussrod. With 12 frets to the body a trussrod is not needed. And I also think that the tone will suffer from the heavy metal.Without the convenience of a trussrod I have to be very careful. First I tap in loose frets in the fretboard to fill out the void and put strings to tension on the guitar. I leave it vibrating with strings at tension for att couple of days to let the neck and the whole guitar settle in. I have my version of the Erlevine neck jig to be able to sand in a very small relief with "strings in tension" on the fretboard before I mount the frets permanently. When released from the jig the neck usually have a back bow with a little extra bow on the top of the fretboard (from the rotation force over the nut to the tuners). I have a CNC made aluminum beam with a small negative relief of 0.1 mm. I use that on the fretboard and also to crown the frets. Only when I've done this I have a nice relief curve on the top of the frets. The 1'th fret is not too high.

One thing I haven't mention is that a short mensur makes the intonation problems worse. The correction in both ends accentuates the shorter the mensur is. The old guitars I work with have typically a mensur of 60-63 cm. Shorter than the typical modern guitar.

Anyway. Intonation on brand new factory made guitars are always lacking. You can improve the intonation a lot without a compensated nut. Customers are easily pleased.

-

>> I have a CNC made aluminum beam ...

Roger, that makes me think you use a compound radius on your fretboards. The arguments pro and con for it are very similar to those concerning nut compensation. That is, many luthiers don't think it makes enough of a difference to bother with, but it definitely improves intonation/playability to some degree.

And BTW, I enjoy your posts.

-

Thanks.

I try not to do a compound radius, but maybe I am! The fretboard is trapezoid and not always flat, I sand more or less in the direction of the strings. But I also use a short radius block to shape the fretboard in the end so maybe I'm not.

I don't have much to say about compound fretboards though, it's mostly an electric guitar thing. Needed with really low string height, a big radius fretboard and the use of the string bending technique. I see what you mean :-)

-

Here's a video that's on our site that my business partner David Collins made. I believe that he comments on nut compensation.

Again much of what you are hearing, Roger could be dealt with simply by skillfully cutting the nut slots properly and MUCH lower than what I see in your pics. I would consider the height that you are displaying on your finished Strat nut to be way too high and unplayable.....

Again the difference between a properly cut nut slot and one that's too high may only be several thou but it's noticeable and appreciated greatly when a skilled Luthier makes someone's ax play like butter.

Regarding what you hear and what I hear I'll bet that my Peterson strobe tuner could care less what either of us hear in so much as it sees intonation issues. We humans are not going to hear 2 cents but we might hear 4 - 5 cents. Regardless a quality strobe tuner sees it all.

-

Totally concur, Hesh, all valid points.... but now that leaves me wondering why MusicMan has seen fit to compensate all of their offerings these days? Particularly the electric basses which are compensated quite a bit.

I played a new (and compensated) MM bass in a store a few months back and it sure seemed to have (for lack of a better description) a sweeter and more pleasing sense of intonation. It'd be interesting to have one in-hand now to put it on the strobe tuner just to be able to put some hard numbers to it.

Great discussion... keeps my mind off the bitter cold out there :)

-

When you get the intonation spot on the guitar sounds better when you struck a chord. The tone is clear and sweet when all the notes in the chord work together.

-

Hey Mike! Happy New Year to You!

I can't comment (on a public forum....;)) as to why a manufacturer may seek to differentiate themselves from the pack. MusicMan makes great products for sure!

It's also true that there are countless examples of major manufacturers doing things that were not ready for prime time such as the lack of break angle for the G string on Fender style bolt on necks. Certainly a great idea in terms of manufacturability and using standard pieces of lumber. For a clear ringing G string for all players though.... not so much....:) And how many millions of them are out here?

Ov*tion is yet another example. They had 1/3 of the US guitar market at one time and now no one wants them..... I suppose when the water starts rising or we baby boomers are on our death beds needing bed pans Ov*tions may become fashionable again....

If I was to take a shot at answering your question without joking... I would remind us why f*ctories don't set-up instruments well. It requires more skilled labor and has some risks associated with it as well. Cut a nut slot too low and the nut has to be replaced or filled, etc.

Compensating a nut and then some set-up with the saddles gets one a more in tune playing instrument without the need for a skilled person to cut the nut slots low and avoids the risk. The client benefits for sure because the thing plays more in tune but it's not the only way to get there and it is more complex as well.

The client suffers as well because the thing is harder to play with higher nuts slots.....

But I am guessing. I am sure though that MusicMan is very interested in providing real value to their clients, that much is clear AND I've always really liked their stuff too!

-

The picture is misleading. The height is measured with feeler gauges.

I do my very best to measure right and cut the nut and saddle right. But I always have a correction session when done and do minor adjustments to the nut and saddle. This last fine tuning is probably impossible to hear for a human, but then I know I've done all I can.

A human ear can hear very small differences in pitch between many strings in a chord in the sum of tones from the strings in the chord.

-

I'm practical oriented and accept the Equal temperament as the best compromise on the guitar. The one we have to work with. Otherwise there will be a lot of moving around frets between songs in different keys!

Even if the theories behind the intonation problem are both useful and interesting, I'm more interested in the things you can do to improve the intonation. The action at the 1'th and 12'th, the relief and the intonation using the nut and saddle are things you can fine tune.

On old guitar the correct (for equal temperament that is) placement of frets is another issue, sometimes the last frets beyond the 12'th are banged in using the naked eyes. They can be 3 mm off!

-

Hippy New Ye Hah Hesh and all,

I was fumbling around and about to post the same link to David's erudite and scientifically reasoned thoughts on compensation. Luthiery is a clinical business conducted by emotional and passionate artisams which sometimes gets in the way of a clear solution to a problem. Nut compensation is one of those things and I recently had one of my best players banging on about just how brilliant a compensated nut sounded on a demo guitar a local luthier proffered for use. I did a short "David Collins" on him and moved on as there was no point in trying to change a mind already made up.

I suppose the best I can say is that nut compensation may support a particular key/chord progression and if one is recording a particular tune a compensated nut designed specifically for that key may be beneficial.

I don't know why Music Man has gone to the trouble of patenting and promoting a compensated nut, maybe it's a "point of difference" marketing thing, maybe it works to solve a problem with their instruments or make a bass sound better.....but, as with a lot of things; we seem to have got on with doing what we do just fine up until this can of worms got back on the menu.

Note, I had a Peterson Strobe long before most of my colleagues and use(d) it to map intonation across the board. My response to what I know from this is to tell players to get some technique lessons and improve their playing style or fix their fingerboard/fret configuration/set-up etc before chasing very lithe rabbits down burrows.with nut tweaking.

Roger makes his points and does his stuff and one cannot doubt his dedication to his craft, however, David Collins uses the science to assist us in working out just what we are looking at and listening to. A giant among men to whom I owe a great debt of gratitude.

Regards,

Rusty.

-

The video Hesh linked to deals primarily with temperament, of which misunderstanding often becomes a major influence in driving some to chase solutions in alternate tuning and intonation methods. The subsequent video in this series is the one which focuses more directly on methods of compensating nuts.

https://youtu.be/NEjekEOMWmg

I've spent a great deal of time working with systems like this, and was once rather enthusiastic about their promise and potential. Over a few decades, much study and experimentation, and thousands of guitars however, I have come to the conclusion that these widgets are largely bandaids for symptoms rather than true solutions, and tend to bring unnecessary side effects which can be avoided by addressing through simple improved setup methods.

I commend anyone willing to embark on this quest for improving common intonation issues through innovative approaches. Having been through this phase myself however, on no small scale mind you, but immersed full time in the demand of very discerning clients, I would suggest that this method of compensation is not an ultimate solution, so much as it may be a step in the process of learning that it's not all it's cracked up to be.

-

Thanks. That's a great educational video.

Didn't know that wolf notes in acoustic guitars affects the tuning, also nice to see the way strings goes out of tune with magnets too close to the strings on an electric guitar. Impressed by the test jig in the beginning of the video.

I need to look into how close I can have the strings above the 1'th fret without buzzing. Maybe I can go down a bit more and don't need as much nut compensation as a result. If you have some standard numbers going for the height between the top of the 1'th fret and the underside of the strings I'd be interested to hear.

With a slope off the pitch will be even higher than the added pitch from the nut compensation from the added string tension. I don't have a slope off on the fretboards on the last frets, I glue a thin wedge under the fretboard if needed to get a nice saddle height at the bridge (when doing the neck reset). My goal is to have the whole fretboard with a very small even relief. Thinking about it the deepest part of the relief should be on the 12'th fret where the string vibrates the most. Doing like I do now puts the deepest dale around the 9'th fret... Hmm. On the other hand the way I do it will counteract the added pitch from the nut compensation putting the strings a bit closer to the fretboard. Another Hmm.

© 2026 Created by Frank Ford.

Powered by

![]()